Pipe Bellows: Essential Components for Flexibility, Safety, and System Longevity

Introduction: Why Pipe Bellows Are Critical in Industrial Systems

Great 👍

Here is Blog 2 (≈2000 words) — written professionally, SEO-optimized, with ONLY ONE hyperlink, exactly as requested.

Pipe Bellows: Essential Components for Flexibility, Safety, and System Longevity

Introduction: Why Pipe Bellows Are Critical in Industrial Systems

Pipe bellows play a crucial role in modern piping systems by absorbing movement, vibration, and thermal expansion. In industries where pipelines are exposed to fluctuating temperatures, pressure changes, and mechanical stress, pipe bellows act as protective components that prevent system damage and failure.

Without pipe bellows, rigid piping systems would be vulnerable to cracking, leakage, and misalignment. By providing controlled flexibility, pipe bellows help maintain system integrity, improve safety, and extend the lifespan of connected equipment.

What Are Pipe Bellows?

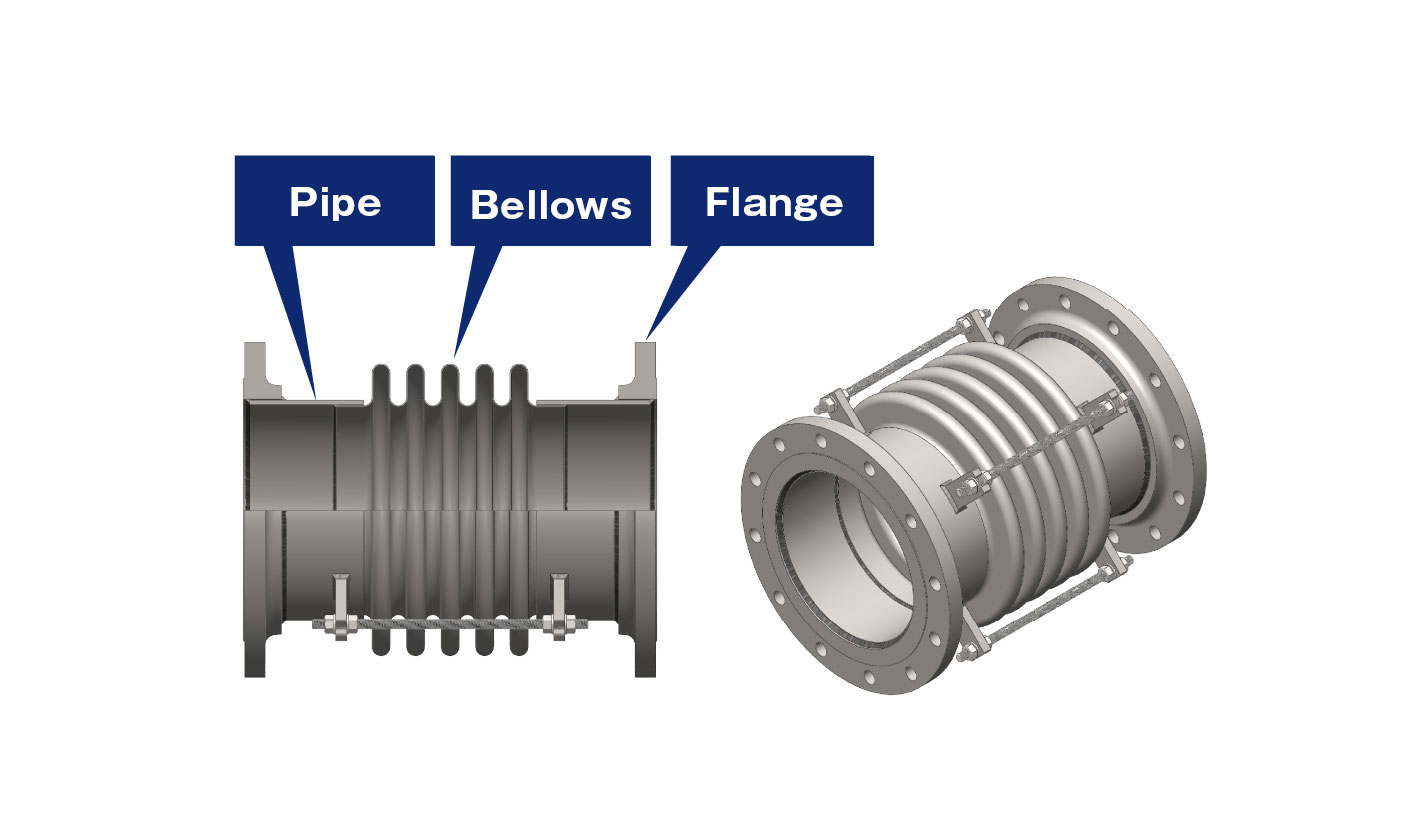

Pipe bellows are flexible, corrugated metal components installed within piping systems to accommodate movement and stress. They are commonly manufactured from stainless steel and engineered to withstand high pressure, temperature variations, and corrosive environments.

Their primary functions include:

-

Absorbing thermal expansion and contraction

-

Reducing vibration transmission

-

Compensating for misalignment

-

Protecting pipes and connected equipment

These functions make pipe bellows essential in industrial, HVAC, power generation, and process piping systems.

Types of Pipe Bellows

Axial Pipe Bellows

Designed to absorb movement along the axis of the pipe, commonly caused by thermal expansion.

Lateral Pipe Bellows

Used to accommodate sideways movement in piping systems where alignment shifts occur.

Angular Pipe Bellows

Handle rotational movement between pipe sections due to directional changes.

Universal Pipe Bellows

Combine multiple movement capabilities, offering greater flexibility in complex systems.

Materials Used in Pipe Bellows Manufacturing

Pipe bellows are typically made from high-grade metals to ensure durability and performance.

Common materials include:

-

Stainless steel (SS 304, SS 316)

-

Alloy steel for high-temperature applications

-

Specialized corrosion-resistant alloys

Material selection depends on pressure, temperature, and environmental conditions.

Why Pipe Bellows Are Necessary in Piping Systems

Thermal Expansion Control

Temperature changes cause pipes to expand and contract. Pipe bellows absorb this movement, preventing stress buildup.

Vibration Reduction

Equipment vibration can transfer to piping systems, causing fatigue. Pipe bellows reduce vibration transmission.

System Protection

By accommodating movement, pipe bellows protect flanges, welds, valves, and connected machinery.

Applications of Pipe Bellows Across Industries

Pipe bellows are widely used in:

-

Oil and gas pipelines

-

Power plants

-

Chemical and petrochemical facilities

-

HVAC and district cooling systems

-

Water treatment plants

Their versatility makes them suitable for both high-pressure and low-pressure applications.

Installation Considerations for Pipe Bellows

Proper installation is critical to ensure performance and longevity.

Key considerations include:

-

Correct alignment and support

-

Use of limit rods and anchors where required

-

Avoiding over-compression or over-extension

-

Following manufacturer specifications

Incorrect installation can significantly reduce bellows lifespan.

Pipe Bellows vs Rigid Piping Solutions

Rigid piping systems lack flexibility and are prone to damage when exposed to movement and stress. Pipe bellows provide controlled flexibility without compromising system integrity.

Benefits over rigid systems include:

-

Reduced maintenance costs

-

Improved safety

-

Longer service life

Maintenance and Inspection of Pipe Bellows

Regular inspection helps identify early signs of wear or damage.

Recommended practices:

-

Visual inspection for cracks or deformation

-

Checking for leakage at joints

-

Monitoring system movement

Timely maintenance prevents unexpected failures and downtime.

Importance of Quality in Pipe Bellows

High-quality pipe bellows are engineered with precise corrugation design, consistent material thickness, and strong end connections. Quality manufacturing ensures:

-

Reliable performance

-

High pressure resistance

-

Long operational life

Choosing inferior bellows can lead to premature failure and costly repairs.

Customization Options for Pipe Bellows

Manufacturers often provide custom pipe bellows based on:

-

Pipe diameter and length

-

Movement requirements

-

Pressure and temperature ratings

-

Connection types

Customization ensures optimal fit and performance for specific applications.

Pipe Bellows in High-Pressure and High-Temperature Environments

Pipe bellows are specifically designed to handle extreme conditions. Proper material selection and engineering allow them to perform reliably even in demanding environments such as power plants and refineries.

Sourcing Quality Pipe Bellows

Selecting a trusted supplier ensures access to pipe bellows that meet industry standards and performance requirements.

To explore high-quality pipe bellows with reliable pipe thread connections for industrial applications, you can visit:

👉 Pipe Bellows

(Only one hyperlink used, exactly as requested.)

Impact of Pipe Bellows on System Efficiency

By reducing stress and preventing damage, pipe bellows contribute to:

-

Improved system reliability

-

Lower maintenance frequency

-

Reduced downtime

-

Enhanced operational efficiency

Their role is critical in long-term system performance.

Future Developments in Pipe Bellows Technology

Advancements in materials and design continue to improve the performance of pipe bellows. Innovations focus on higher fatigue life, improved corrosion resistance, and better movement absorption.

Conclusion: Flexible Protection for Modern Piping Systems

Pipe bellows are indispensable components in modern piping systems. By absorbing movement, reducing vibration, and protecting equipment, they ensure safety, reliability, and efficiency.

Investing in quality pipe bellows and proper installation safeguards piping infrastructure and supports uninterrupted industrial operations.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness